Understanding Water Recycling

Water recycling is the process of treating used water so that it can be reused for various purposes. In factories, this often means capturing wastewater, treating it, and then using it again in the production process.

This method helps to minimize water consumption and reduces the amount of wastewater that needs to be disposed of. For many factories, water recycling is not just an option but a necessity for efficient and sustainable operations.

Also Read: Essential Insights on Organic Cotton: 5 Reasons to Switch

The Importance of Water Recycling in Factories

- Resource Conservation: Water is a finite resource, and its availability is increasingly becoming a global concern. Factories that recycle water help conserve this precious resource, ensuring that less fresh water is drawn from natural sources.

- Cost Savings: Treating and reusing water can significantly cut down on costs associated with water procurement and wastewater treatment. By investing in water recycling systems, factories can reduce their utility bills and lower overall operational expenses.

- Environmental Impact: Reducing the volume of wastewater released into the environment can help prevent pollution and mitigate the impact on local ecosystems. This is especially important in areas where water resources are already stressed.

- Regulatory Compliance: Many regions have strict regulations regarding water usage and wastewater discharge. By adopting water recycling practices, factories can ensure compliance with these regulations and avoid potential fines.

- Operational Efficiency: Recycling water can enhance operational efficiency by providing a reliable and consistent supply of water for production processes. This helps in maintaining production schedules and reducing downtime.

How the Factory Implements Water Recycling

At our featured factory, water recycling is a core component of their sustainability strategy. Here’s a closer look at how they implement this practice:

- Wastewater Collection: The factory has established a comprehensive system to collect wastewater from various stages of production. This includes runoff from manufacturing processes, cleaning activities, and other sources of used water.

- Treatment Facilities: The collected wastewater is directed to treatment facilities where it undergoes various purification processes. This may include filtration, chemical treatment, and biological processes to remove contaminants.

- Recycling Systems: Once treated, the water is tested to ensure it meets quality standards before being reused. The factory has set up recycling systems that channel this purified water back into the production line.

- Monitoring and Maintenance: To ensure the effectiveness of the water recycling system, the factory regularly monitors water quality and system performance. Maintenance schedules are strictly followed to address any issues promptly.

- Employee Training: The factory invests in training programs for employees to raise awareness about the importance of water recycling and to encourage practices that support the recycling efforts.

Benefits Realized by the Factory

The factory’s dedication to water recycling has yielded several benefits:

- Significant Water Savings: By recycling water, the factory has reduced its reliance on fresh water sources by a substantial margin. This not only helps conserve water but also reduces the strain on local water supplies.

- Cost Reduction: The factory has seen a noticeable decrease in water-related expenses. Savings from reduced water procurement and wastewater treatment costs have been redirected towards further sustainability initiatives.

- Enhanced Reputation: Committing to water recycling has bolstered the factory’s reputation as an environmentally responsible business. This has positively impacted relationships with stakeholders, including customers and regulatory bodies.

- Compliance Assurance: The factory’s proactive approach to water recycling ensures that it remains compliant with environmental regulations, minimizing the risk of legal issues and fines.

- Operational Stability: With a reliable source of recycled water, the factory has experienced fewer disruptions in production, contributing to smoother operations and better overall efficiency.

Read More: Introducing Natural Cotton: Embracing Our Organic Roots

Future Plans and Innovations

The factory is not resting on its laurels. They are continually exploring new technologies and methods to improve their water recycling processes. Some future plans include:

- Advanced Treatment Technologies: Investing in cutting-edge treatment technologies to further enhance the quality of recycled water.

- Expanding Recycling Capacity: Increasing the capacity of their recycling systems to handle a larger volume of wastewater and support growing production needs.

- Collaborations and Research: Partnering with research institutions to explore innovative solutions and best practices in water recycling.

- Community Engagement: Sharing their experiences and strategies with other businesses and community members to promote wider adoption of water recycling practices.

- Sustainability Goals: Setting ambitious sustainability goals that include further reductions in water usage and improvements in overall environmental impact.

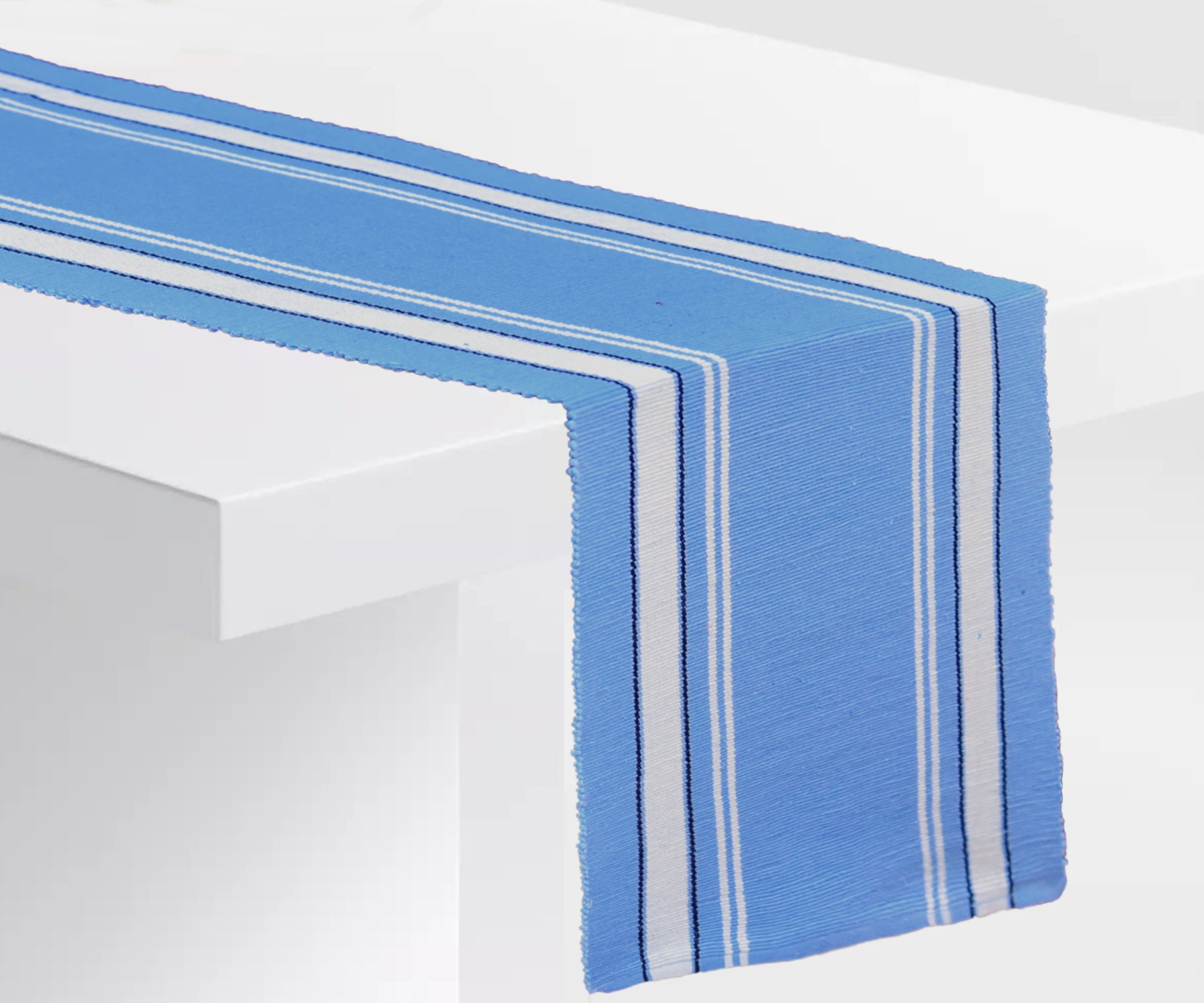

Discover sustainable choices at All Cotton and Linen. Shop now for eco-conscious products that make a difference.

The factory’s dedication to water recycling is a powerful example of how businesses can take meaningful steps towards sustainability. By conserving resources, reducing costs, and minimizing environmental impact, the factory not only benefits itself but also contributes to a more sustainable future.

As more factories follow suit and adopt similar practices, the collective effort will play a crucial role in addressing global water challenges and promoting environmental stewardship.

Related Readings

- Sustainable Practices in Industrial Wastewater Management – An exploration of industrial wastewater management techniques.

- Water Stewardship at Unilever – Unilever's approach to responsible water usage and sustainability.

- Toshiba’s Water Recycling Solutions – Toshiba's innovative water recycling technologies for industries.

- Scientific Insights on Water Recycling – A scientific article detailing recent advancements in water recycling.

- The Role of Water Recycling in Sustainable Development – How water recycling contributes to broader sustainability goals.